Wheeled Harvester - 1470G

- Net Power: 200 kW (268 hp) at 1,600–2,000 rpm

- Pump Capacities: 210 cm3 (13 cu. in.) / 180 cm3 (11 cu. in.)

- Boom Reach: 8.6 m (28.2 ft.) / 10 m (32.8 ft.) / 11.0 m (36.1 ft.)

Features

CH9 10 m boom on a 1470G wheeled harvester

CH9 10 m boom on a 1470G wheeled harvester

For ultimate harvesting productivity, choose the stable and smooth 1470G Wheeled Harvester. Equipped with its CH9 rigid boom that delivers precise control, the 1470G is perfect for tackling large timber and extreme conditions.

- Simple and durable structure with single-telescope extension

- Parallel design makes boom move straight forward or upward with single joystick command

- Rigid design and precise control

Stacked cooling system on a wheeled harvester

Stacked cooling system on a wheeled harvester

The hydraulically driven, variable-speed reversing fan runs at the required speed for optimal cooling, reducing fuel consumption as a result. It’s programmable to reverse at periodic intervals to help reduce debris buildup, or it can be actuated at the push of a button if demanded by operating conditions. The reversing fan and side-by-side-by-side cooler arrangement enables efficient cooling and allows for easy cleaning as required.

- Variable-speed fan helps to reduce fuel consumption

- In colder temperatures the fan speed is reduced to meet machine cooling requirements

- Cooling fan automatically reverses to help remove debris at programmable intervals or manually activating the reversing fan feature on the operator control panel

Mobile device using JDLink™

Mobile device using JDLink™

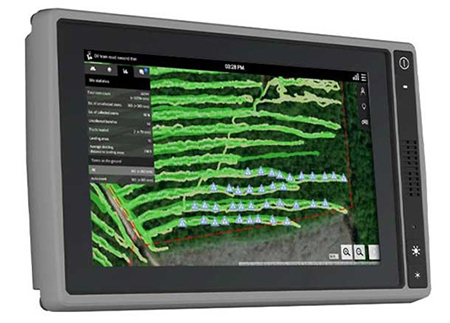

TimberMatic™ Maps monitor displaying live production data

TimberMatic™ Maps monitor displaying live production data

Machine Health Monitoring Center

Machine Health Monitoring Center

Now included in base machine, the JDLink telematic system provides the foundation for John Deere’s Precision Forestry solutions. These systems help optimize your machine, your uptime, and your jobsites, which ultimately lead to improved production efficiency.

- JDLink connectivity enables you to view several parameters of your machine, including its location, fuel level, average fuel burn rate, idle time, machine utilization, and much more

- When enabled, John Deere Connected Support™ allows the dealer to provide remote diagnostics, rapid service response with the right part in hand, and parts availability; all to maximize machine uptime

- John Deere’s centralized Machine Health Monitoring Center analyzes data from thousands of connected machines, identifies trends, and develops recommended actions to help prevent downtime

- TimberMatic Maps gives enhanced visibility to the jobsite, which streamlines communication and increases efficiency

- TimberManager™ provides remote visibility to your operation from any device, allowing you to make smart business decisions based on real-time production data

1070G with IBC

1070G with IBC

Intelligent Boom Control (IBC) smooths boom operations, making them more precise and efficient, to increase operator productivity compared to a wheeled harvester without IBC. With IBC, you no longer need to control each boom function independently. Just control the direction of the head with a single lever command, and IBC will automatically guide the boom and cylinders accordingly. IBC also utilizes adaptive swing control to adjust the swing speed based on the overall position of the head. This makes controlling the head more precise and intuitive, especially for new operators, compared to machines without IBC.

Benefits

- Customizable control pattern and boom motions

- More efficient and consistent boom movements

- IBC functions have been adapted to the work cycle

- Automatic adjusting of the harvester head in accordance with the trajectory of the boom

- Reduces operator fatigue and increases operator comfort

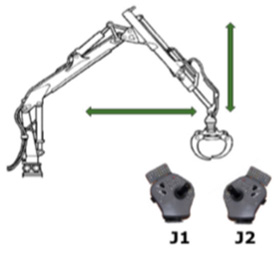

IBC, basic functionality

- Operator controls, boom tip directly instead of controlling individual joints and extension

- Joystick 1: Boom tip forwards and backwards

- Joystick 2: Boom tip up and down

- System includes electronic cylinder end dampings

- Desired boom speed (with same joystick position) remains regardless of boom positions - automation combines movements together.

- Thus boom accuracy gets better especially with long boom reach

Diagram showing the use of the joysticks for IBC

Diagram showing the use of the joysticks for IBC

View out the front window of a wheeled harvester

View out the front window of a wheeled harvester

The standard RENCRAFT® Super Hard Coat polycarbonate windows are scratch resistant, easy to clean and optically enhanced. These windows fulfill ISO 21876 standard for saw-chain shot protection. The cab window is now 50% thicker material than previous windows, the cab is better insulated and quieter, too.

- Scratch resistant

- Easy to clean

- Better insulated

- Quieter cab

- Helps operators to see operation of machine

Wheeled Harvester with cab rotated for full visual of harvesting head

Wheeled Harvester with cab rotated for full visual of harvesting head

The cabin is mounted on a geared rotary bearing placed on top of hydraulic cylinders. It is leveled by hydraulic cylinders and turned by hydraulic motors with gears.

The cabin follows the boom slew and remains automatically in upright orientation but can also be operator-controlled. Boom following and leveling functions can be adjusted by the operators' preferences; offset and delay between cabin and boom movements and the behavior of leveling can be adjusted. The cabin turns 160°.

Grease nipples for manual greasing of the turning mechanism and lower ends of the levelling cylinders are gathered on the left side of the cabin platform.

Automatic air conditioning is a standard feature.